How Resilient is Your Supply Chain in the State of Disruptions?

Global supply chain disruptions pose considerable challenges for companies. Effectively addressing these disruptions necessitates agile and responsive risk management capabilities. Over 80% of procurement leaders claim that dealing with supply chain disruptions has been their most significant challenge. An aspect often overlooked but holds immense significance is resiliency in the supply chain. In this article, we’ll delve into the crucial role of supply chain resilience and explore the fundamental components of establishing a digitally empowered, adaptable, and robust supply chain.

What is Supply Chain Resiliency?

Supply chain resilience involves the capacity to identify and address disruptions while upholding core functions swiftly. Imagine a company that relies heavily on a single supplier for a critical component. A resilient supply chain will have alternative suppliers in place if that supplier faces a production halt due to unforeseen circumstances like a natural disaster. This strategic preparation allows the company to continuously flow the essential components, preventing extensive production delays and financial losses. In essence, supply chain resilience aims to create a robust framework that enables organizations to maintain financial stability and operational effectiveness despite unpredictable disruptions.

In the words of The Federal Emergency Management Agency (FEMA), Supply chain resilience is the ability of a preexisting network of demand and supply to deploy surviving capacity and/or introduce new capacity under severe duress. It is the ability of a network, or portion of a network, to continue moving (directing, redirecting, flowing) goods and services even when essential network elements are no longer operating. For example, the continued flow of water, food, and fuel while the electric power grid is not operating would express supply chain resilience.

Roadblocks to Supply Chain Resilience

Transportation and Logistics Disruptions

Transportation bottlenecks can lead to imbalances in inventory levels. Delayed shipments result in shortages of raw components, affecting manufacturing operations. Relying on a specific carrier or a single transportation mode can result in lead time variability and other supply chain breakdowns. This can harm customer relationships, increase operational costs, and damage brand reputation.

For example, since pandemic-era upheavals, the Panama Canal, where water serves as the lifeblood for its lock-driven operations, has recorded low water levels. Canal authorities have imposed restrictions on daily traffic and vessel weights, causing a backlog of vessels waiting to pass. These canal limitations have disrupted global trade by causing strain on consumer goods prices, as shipping delays and additional charges increase shipping costs. Consider a supply chain visibility platform that lets organizations identify bottlenecks and inefficiencies and help you make the right decisions at the right time.

Technological Barriers

Implementing new technologies means requiring skilled professionals. Professionals with limited technical skills may handle data, resulting in legal consequences. Introducing new technologies can pose integration challenges – affecting work productivity, causing delivery delays, and leaving data privacy and security at risk.

Demand Volatility

Unpredictable shifts in demand make accurate forecasting a daunting task. With poor forecasting, supply chains may produce excess inventory, tying up capital and increasing the risk of product obsolescence. In contrast, inventory shortages during periods of unexpectedly high demand can weaken the supply chain’s resilience.

Sustainability Concerns

Growing sustainability standards and regulations can impact supply chain operations. According to PwC, 8 out of 10 consumers will pay 5% more for sustainable products. A lack of consideration for sustainability can lead to resource scarcity and disruptions in the long run. As non-renewable resources deplete, supply chains heavily dependent on these resources can face production delays and potential material shortages.

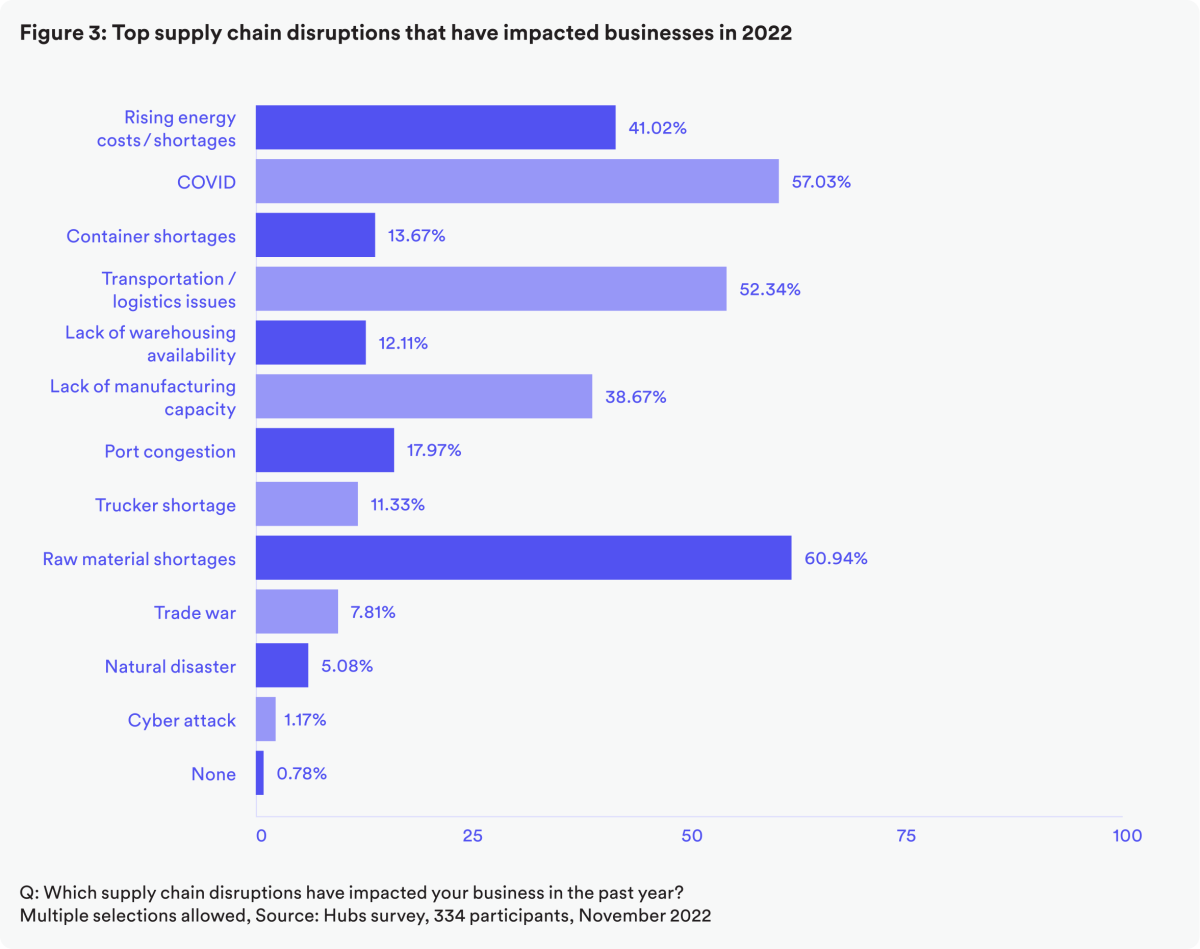

Resilience in Supply Chain: A Buzzword or More?

According to HUBS, 77% of companies suffered an external disruption to their supply chain during 2022, with shortage of materials as the major challenge. For the global supply chain, the impact of disruptions is not limited to businesses – it reverberates across the global economy. That’s why resiliency has become essential for companies looking to build a more robust and efficient supply chain. A resilient supply chain anticipates disruptions and mitigates the effects of such disruptions through a combination of strategies. Automated processes, digitalization, diversified suppliers, and robust cybersecurity are some standard practices organizations can take to reinforce their supply chain and ensure better and more reliable performance in the long run.

Why Resilience Should Be a Priority for Your Supply Chain Business

Risk Mitigation

Risk mitigation is about navigating disruptions and reducing potential threats’ impact. These risk-management strategies help minimize risks and make the supply chain resilient:

- Identify high-risk scenarios and develop contingency plans to mitigate the potential fallout.

- Avoid risk exposure by diversifying suppliers, creating alternate sourcing strategies, or steering clear specific transportation routes prone to vulnerabilities.

- Limit risks by establishing agile relationships with suppliers who can proactively adjust to demand fluctuations.

- Transfer risk by outsourcing certain operations like payroll services, customer services, etc., to reduce the impact on own operations and focus on core competencies.

Cost Management

Expedited shipping, production slowdowns, or alternative sourcing leads to increased costs. A resilient supply chain helps companies manage costs by strategically positioning inventory and resources closer to markets or customers and eliminating the need for expedited shipping and associated costs. By integrating advanced data analytics and encouraging supplier collaboration, companies can maintain steady production schedules and inventory levels, reducing overstock and inventory-carrying costs.

Continued Business Operations

Companies with resilient supply chains can quickly adapt to demand fluctuations and disruptions. When companies regularly assess and improve existing strategies to manage new risks and changing business conditions, they can continue operations during adverse conditions. With streamlined processes, companies can prevent production delays, revenue loss, and reputational damage that might arise when customer demands are unmet.

Competitive Advantage

Supply chain systems built ten years ago to support business processes are severely handicapped to adapt to the evolving business landscape. Digital supply chains enable optimized production, sales, and operations – leading to cost savings and effective business performance. A robust and agile supply chain helps companies seize growth opportunities and capture market share from less-prepared competitors. The flexibility allows companies to pivot to changing situations promptly.

Key Strategies to Build Resilient Supply Chains

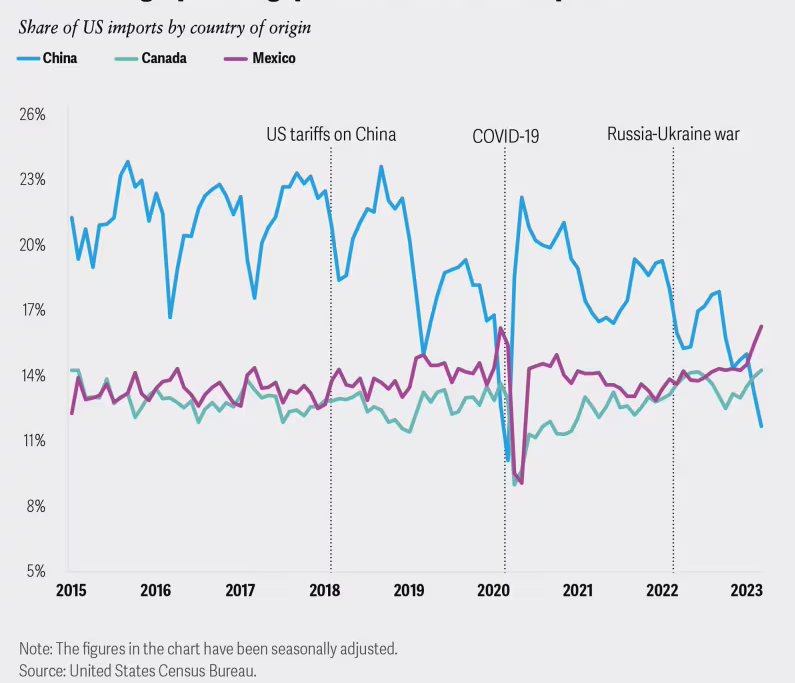

Adopt Nearshoring

Nearshoring is gaining traction because it can accelerate time-to-market and reach the end customer quickly. However, it can be costly for supply chain organizations and affect product quality. With a near-shoring approach, businesses can take ocean logistics out of the picture, eliminate geographical dependence on worldwide networks, and reduce lead times. Nearshoring helps businesses limit their vulnerability to shipping problems and geopolitical tensions.

Leverage Technology Platforms

Supply chain digitalization and modern technologies provide businesses the resilience to adapt rapidly to disruptions and achieve optimized performance. Automated tools help organizations eliminate excessively dangerous or repetitive human tasks. According to Gartner, 50% of supply chain organizations will have invested in artificial intelligence and advanced analytics by 2024. With artificial intelligence, predictive analytics, and data analysis, organizations can forecast demand and risk and recommend actions based on them.

Streamline Risk Management

Developing a risk mitigation plan is half the battle won in addressing potential disruptions. According to a recent survey, about 70% of businesses ramp up their investment in supplier risk detection. Gartner predicts that by 2025, supply chain risk management will be a crucial success driver for over 50% of organizations. A risk management approach helps organizations predict the fallout of events with low predictability and severe impact and minimize vulnerabilities.

Strengthen Supplier Communication

Fostering cross-functional collaboration enables supply chains to manage exceptions, mitigate risks, and address issues effectively. Collaboration doesn’t mean joint decision-making. Still, decisions taken by supply chain stakeholders must align to enable a supply chain to respond proactively to any disruption. By enabling supplier collaboration, Quloi promotes effective communication and information sharing, leading to streamlined processes, reduced lead times, and improved overall supply chain performance.

The Path Forward is Clear

Get in Touch with our industry experts to learn how we help organizations achieve supply chain resilience by measuring and mitigating risk while optimizing operational performance.