How Comprehensive Supplier Scorecards Can Elevate Your Business Performance

Supply chains are the lifeblood of any business, and companies are relentlessly pursuing strategies to maximize profitability and uphold the highest quality standards for their products and services. In this pursuit, suppliers play a pivotal role as the linchpin of operations.

Picture your business as a finely tuned machine, with suppliers as the essential gears that keep it running seamlessly. They provide the critical components and services that drive your success. Yet, maintaining these gears in top-notch condition and ensuring peak performance can be a complex challenge.

To meet this challenge head-on, businesses need a powerful tool in their arsenal: comprehensive supplier performance scorecards. These scorecards offer a clear, data-driven perspective on supplier performance, giving companies the insights they need to make informed decisions, boost efficiency, and consistently uphold the highest quality standards throughout their supply chain.

Traditional vs. Comprehensive Supplier Performance Evaluation

For the longest time, traditional evaluation methods have been the go-to method for organizations when assessing supplier performance. These methods encompass a range of techniques, including supplier audits, surveys, and qualitative assessments. While these methods have undoubtedly played a crucial role in gauging supplier performance, they are beginning to show their limitations as supply chains evolve and supplier relationships grow more complex.

Traditional supplier evaluation methods come with inherent flaws. Quantitative assessments often rely on data extracted from ERPs or other tools, and this data may not capture all the nuanced information required. Furthermore, transferring this data into spreadsheets can introduce errors, leading to inaccurate evaluations.

On the contrary, qualitative assessments, while valuable, can be susceptible to personal biases, resulting in inconsistent results and hindering data-driven decision-making. Moreover, traditional methods typically provide only snapshots of supplier performance, rendering them ill-suited to the fast-paced supply chain environment. These static evaluations may fail to capture the dynamic nature of supplier relationships and how they impact operational efficiency.

Comprehensive Supplier Performance Evaluation: A Holistic Approach

In response to the limitations of traditional methods, a robust and adaptable solution has emerged: comprehensive supplier performance evaluation through 360-degree scorecards. This approach combines quantitative metrics like delivery timeliness, cost-effectiveness, and quantity accuracy with qualitative dimensions such as product quality, communication effectiveness, collaboration, and adherence to compliance standards. By assessing both “what” (quantitative) and “how” (qualitative), organizations gain a nuanced and accurate understanding of supplier performance.

This approach offers a more faithful reflection of actual supplier performance. It captures aspects like collaboration, communication, and quality—elements often crucial in determining the success of a supplier relationship. By evaluating not just “what” was delivered but “how” it was delivered, organizations can make well-informed decisions that fortify supplier relationships, mitigate risks, and drive operational excellence.

Understanding Comprehensive Scorecards

Comprehensive supplier scorecards are structured frameworks that assess and track supplier performance across various dimensions critical to an organization’s objectives. Importantly, they can be applied to businesses of all sizes.

Negotiating with Existing Suppliers

Scorecards serve as a compelling tool to highlight areas where a supplier needs improvement for the business relationship to continue. This can lead to favorable outcomes, including better pricing or more favorable terms for procurement.

Selecting New Suppliers

When deciding whether to collaborate with a potential supplier, scorecards can benchmark their performance against current suppliers, aiding in informed decision-making.

Identifying Potential Hazards

Scorecards are important in identifying risks associated with working with a particular supplier. This encompasses assessing their financial stability, supply chain reliability, product or service quality, and delivery timelines.

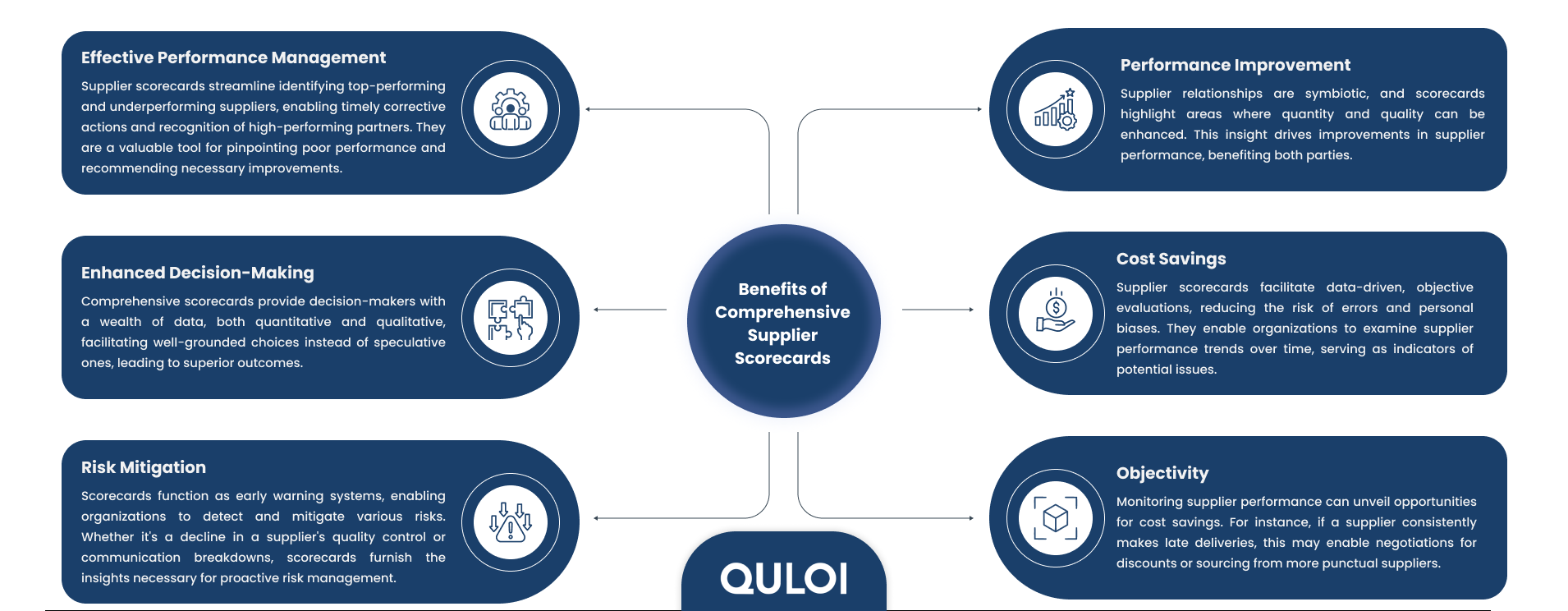

Benefits of Comprehensive Supplier Scorecards

Effective Performance Management

Supplier scorecards streamline identifying top-performing and underperforming suppliers, enabling timely corrective actions and recognition of high-performing partners. They are a valuable tool for pinpointing poor performance and recommending necessary improvements.

Enhanced Decision-Making

Comprehensive scorecards provide decision-makers with a wealth of data, both quantitative and qualitative, facilitating well-grounded choices instead of speculative ones, leading to superior outcomes.

Risk Mitigation

Scorecards function as early warning systems, enabling organizations to detect and mitigate various risks. Whether it’s a decline in a supplier’s quality control or communication breakdowns, scorecards furnish the insights necessary for proactive risk management.

Cost Savings

Monitoring supplier performance can unveil opportunities for cost savings. For instance, if a supplier consistently makes late deliveries, this may enable negotiations for discounts or sourcing from more punctual suppliers.

Objectivity

Supplier scorecards facilitate data-driven, objective evaluations, reducing the risk of errors and personal biases. They enable organizations to examine supplier performance trends over time, serving as indicators of potential issues.

How to Implement Comprehensive Scorecards

Define Clear Objective

Begin by articulating specific objectives for your scorecards. Determine the factors for the success of your projects. For each factor, ask questions such as, “If the supplier doesn’t perform well in this area, will it pose problems?” or “Does this impact the broader business, and is there a process to mitigate this risk?”

Customize KPIs

Tailor the scorecard to your organization’s unique needs by selecting the right KPIs encompassing quantity and quality dimensions. Consider your business goals, key suppliers, and areas ripe for improvement. Begin with a reasonable number of KPIs to ensure manageable evaluations.

Example of KPIs

Delivery Performance

Tracking the consistency of on-time deliveries over various periods.

Quality

Assessing the quality of supplies or raw materials each vendor provides.

Lead Time

Measuring the time between production and delivery for each product or material supplied.

Shipping Costs

Evaluating the overall cost of shipping supplies and materials from the vendor.

Assign Weights

Determine appropriate weights for each KPI based on their relative importance to your strategic goals. This weighting ensures that the most critical aspects receive attention in the evaluation process.

Determine Your Grading Scale

The grading scale on a supplier scorecard visually represents the vendor’s value to your organization. This can be a traditional letter grade scale, with “F” representing the lowest performance and “A” signifying the highest or a numerical scale. Define what each grade means and how many opportunities for improvement are provided.

Best Practices for Supplier Evaluation through Scorecards

Start Small and Simple

If you’re new to supplier scorecards, begin with a few KPIs for a select group of suppliers and progressively expand complexity as you become more comfortable with the process.

Be Transparent with Your Suppliers

Effective supplier performance management goes beyond tracking metrics; it’s about nurturing partnerships and relationships. Therefore, be as transparent as possible with your suppliers. Ensure they understand how they are being assessed and what steps will be taken if expectations are unmet.

Ensure Data Accuracy

Supplier scorecards are only as reliable as the data entered. Avoid manual data entry errors by adopting modern tools like supplier performance management systems to ensure accuracy and real-time data updates.

Seek Feedback and Collaboration

Schedule regular conversations with your suppliers to discuss performance, identify areas for improvement, and be receptive to their feedback. Effective communication is the cornerstone of successful supplier relationships.

Continuous Monitoring

Implement ongoing performance tracking to ensure the scorecard remains relevant and actionable. Regularly revisit your KPIs to verify their continued relevance and adapt them as needed.

Manage Supplier Scorecards with Quloi

Supplier performance evaluation should be collaborative, marked by transparent communication between buyers and suppliers. As supply chains evolve, embracing technology-driven solutions like Quloi is imperative to streamline the scorecard process and ensure success in the dynamic world of supplier management.

Quloi’s collaborative platform transforms order management by centralizing data, offering complete visibility into order changes and supplier performance. Every purchase order change is tracked, providing insight into shifts in lead times, pricing, response times, quantities, and delivery dates.

Are you ready to get started?

Get in touch with our experts today!